We're Open and Ready For New Projects

In this unprecedented time, we wanted to share our action plan to ensure our employees and their families are safe, while protecting you, your...

In this unprecedented time, we wanted to share our action plan to ensure our employees and their families are safe, while protecting you, your...

We retooled precisetooling.com. It's more intuitive, whether you're looking for photos of recent projects, wanting to learn about our capabilities,...

The current issue of The American Mold Builder (shown above) explains how our diversified business model has enabled steady growth while ensuring...

Precise Tooling CEO Don Dumoulin met with Congressman Greg Pence earlier this week to discuss US/China trade issues and the ongoing challenge of...

We're delighted to share exciting news about two members of the Precise leadership team.

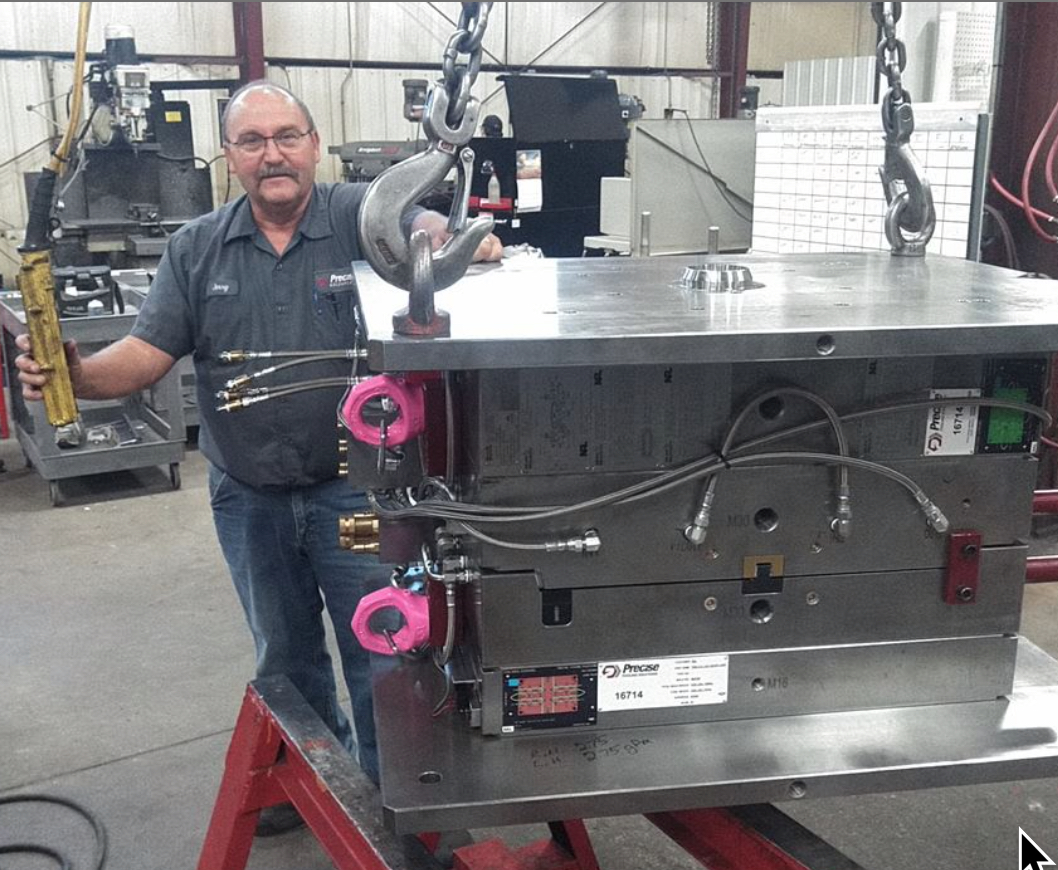

This morning's blog at MoldMaking Technology features our very own Jerry Ward.

We couldn't have said it any better ourselves.

...

We continue to grow. Every week brings new customers for our Injection Tooling, CNC Projects & Ergonomic Lift Tables. Our continued growth means...

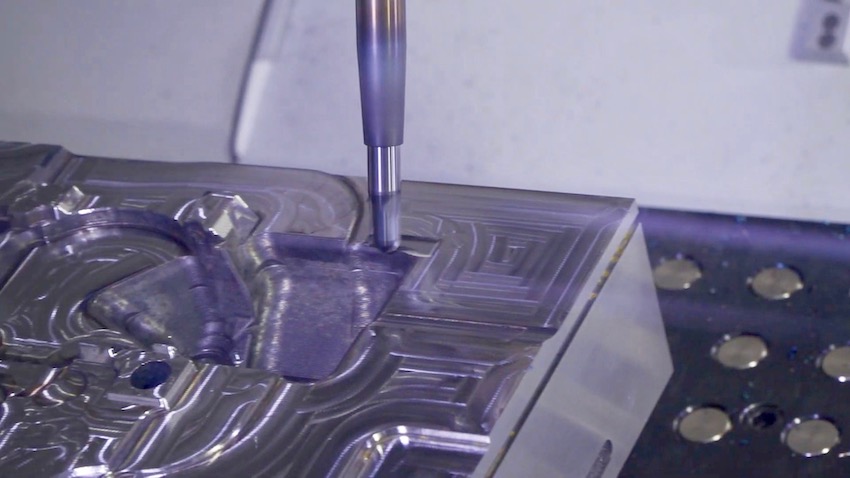

Thermoset molds using bulk molding composites (BMC) are required in situations where the plastic part must withstand high temperatures. Automotive...

Here's an excellent article about the value of vocational programs offered by community colleges. Growing manufacturers like Precise Tooling actively...

Precise Tooling Solutions, Inc. is a specialty manufacturer that builds and repairs injection tooling. We are recognized for our expertise with tight-tolerance optical lighting tools & thermoset molds. We also manage complex CNC machining projects and build ErgoSmart, a line of adjustable-height workstations and lift tables which manufacturers use for assembly and material handling applications. We also have a thorough top of the line equipment list.

© 2019 PRECISE TOOLING SOLUTIONS, INC. ALL RIGHTS RESERVED SITEMAP

PRIVACY POLICY | WEBSITE DISCLAIMER & COPYRIGHT NOTICE | EQUIPMENT LIST