Inspection & Measurement Technology

The January 2021 issue of MoldMaking Technology includes a Q&A with CEO/Owner Don Dumoulin on the use of inspection & measurement technology to drive...

The January 2021 issue of MoldMaking Technology includes a Q&A with CEO/Owner Don Dumoulin on the use of inspection & measurement technology to drive...

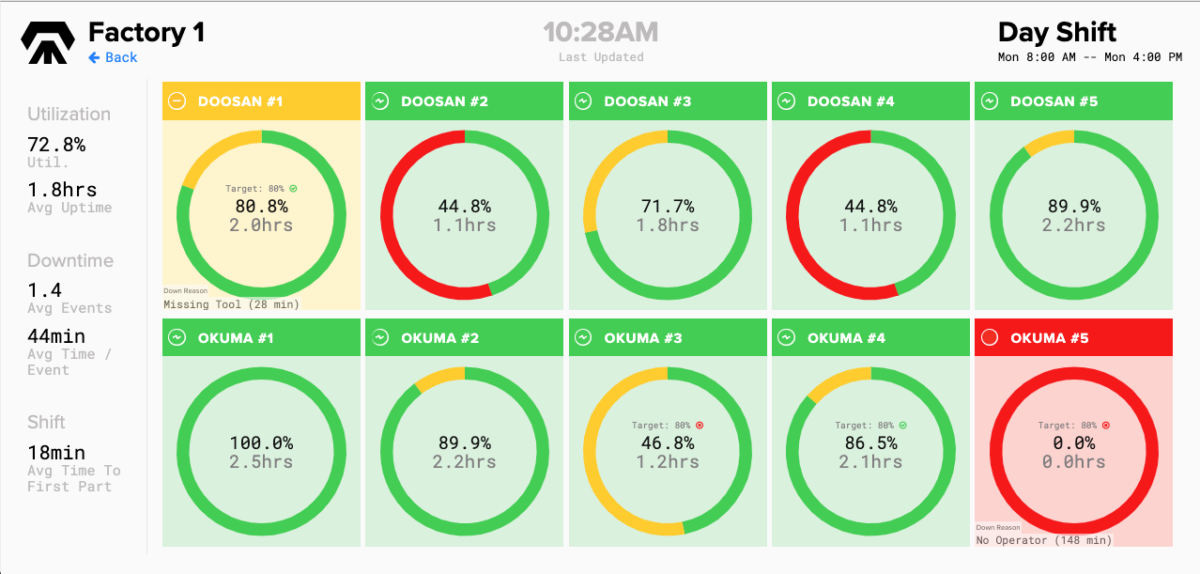

Don Dumoulin, Owner/CEO of Precise Tooling Solutions, discusses his company’s journey to find and implement a machine monitoring solution to collect...

The December issue of MoldMaking Technology includes a Q&A with CEO/Owner Don Dumoulin on the importance of cutting tools for today's high speed...

Several schools told us they need a viral barrier to use as room dividers, between lab tables and in common areas like cafeterias. So, we've designed...

A mid-level shelf is now available for ViralBarrier, our effective and affordable barrier that prevents transmission of the coronavirus that causes...

Press Release - Columbus, IN: Specialty manufacturer Precise Tooling Solutions has introduced ViralBarrier, an effective and affordable mobile...

We're honored that MoldMaking Technology just announced Precise Tooling Solutions as their 2020 Leadtime Leader Award recipient. Now in its 17th...

Modern Machine Shop and other Gardner Business Media properties have been seeking insight about how manufacturers are responding to the ongoing...

Precise Tooling Solutions, Inc. is a specialty manufacturer that builds and repairs injection tooling. We are recognized for our expertise with tight-tolerance optical lighting tools & thermoset molds. We also manage complex CNC machining projects and build ErgoSmart, a line of adjustable-height workstations and lift tables which manufacturers use for assembly and material handling applications. We also have a thorough top of the line equipment list.

© 2019 PRECISE TOOLING SOLUTIONS, INC. ALL RIGHTS RESERVED SITEMAP

PRIVACY POLICY | WEBSITE DISCLAIMER & COPYRIGHT NOTICE | EQUIPMENT LIST